๏ Design & Development ๏

Designed as project ADO15 (Austin Drawing Office project number 15), the Mini came about because of a fuel shortage.In 1956 as a result of the Suez Crisis, which reduced oil supplies, the United Kingdom saw the re-introduction of petrol rationing. Sales of large cars slumped, and there was a boom in the market for so called Bubble cars, which were mainly German in origin. Leonard Lord, the somewhat autocratic head of BMC, decreed that something had to be done and quickly. He laid down some basic design requirements: the car should be contained within a box that measured 10 × 4 × 4 feet (3 × 1.2 × 1.2 m); and the passenger accommodation should occupy six feet (1.8 m) of the 10 foot (3 m) length; and the engine, for reasons of cost, should be an existing unit. Issigonis, who had been working for Alvis, had been recruited back to BMC in 1955 and, with his skills in designing small cars, was a natural for the task. The team that designed the Mini was remarkably small: as well as Issigonis, there was Jack Daniels, who had worked with him on the Morris Minor, Chris Kingham, who had been with him at Alvis, two engineering students and four draughtsmen. Together, by October 1957 they had designed and built the original prototype, which was affectionately named 'The Orange Box' because of its colour.

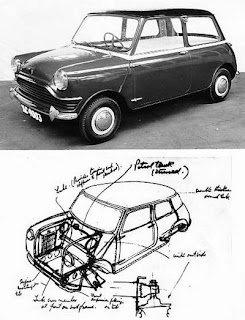

Designed as project ADO15 (Austin Drawing Office project number 15), the Mini came about because of a fuel shortage.In 1956 as a result of the Suez Crisis, which reduced oil supplies, the United Kingdom saw the re-introduction of petrol rationing. Sales of large cars slumped, and there was a boom in the market for so called Bubble cars, which were mainly German in origin. Leonard Lord, the somewhat autocratic head of BMC, decreed that something had to be done and quickly. He laid down some basic design requirements: the car should be contained within a box that measured 10 × 4 × 4 feet (3 × 1.2 × 1.2 m); and the passenger accommodation should occupy six feet (1.8 m) of the 10 foot (3 m) length; and the engine, for reasons of cost, should be an existing unit. Issigonis, who had been working for Alvis, had been recruited back to BMC in 1955 and, with his skills in designing small cars, was a natural for the task. The team that designed the Mini was remarkably small: as well as Issigonis, there was Jack Daniels, who had worked with him on the Morris Minor, Chris Kingham, who had been with him at Alvis, two engineering students and four draughtsmen. Together, by October 1957 they had designed and built the original prototype, which was affectionately named 'The Orange Box' because of its colour.The ADO15 used a conventional BMC A-Series four-cylinder water-cooled engine, but departed from tradition by having it mounted transversely, with the engine-oil-lubricated, four-speed transmission in the sump, and by employing front-wheel drive. Almost all small front-wheel-drive cars developed since have used a similar configuration. The radiator was mounted at the left side of the car so that the engine-mounted fan could be retained, but with reversed pitch so it blew air into the natural low pressure area under the front wing. This location saved precious vehicle length, but had the disadvantage of feeding the radiator with air that had been heated by passing over the engine.

The suspension system, designed by Issigonis's friend Alex Moulton at Moulton Developments Limited, used compact rubber cones instead of conventional springs. This led to a rather raw and bumpy ride, but this rigidity, together with the wheels being pushed out to the corners of the car, gave the car its famous go kart-like handling. It was initially planned to use an interconnected fluid system, similar to the one which Issigonis and Moulton were working on in the mid-1950s at Alvis, but the short development time of the car meant this was not be ready in time for the Mini's launch. The system intended for the Mini was further developed to become the hydrolastic system and was first used on the Austin 1100 (launched in 1962). Ten-inch wheels were specified, so new tyres needed to be developed, the initial contract going to Dunlop.

The car was designed with sliding windows in the doors, thus allowing for storage pockets to be fitted in the space where a winding window mechanism would have been. Issigonis is said to have sized the resulting storage bins to take a bottle of his favourite Gordon's Gin. The boot lid was designed with the hinges at the bottom so that the car could be driven with it open to increase luggage space. On early cars the number plate was hinged so it dropped down to remain visible when the boot lid was open.

To keep labour costs down, the car was designed with quirky welded seams that are visible on the outside of the car running down the A and C pillars and between the body and the floor pan. To further simplify construction, the car had external door and boot hinges.

This cross-sectioned Mini demonstrates how passenger space is maximised.All of these novel and elegant technical innovations resulted in a car with minimum overall dimensions yet maximised space for passengers and luggage.

Production models differed from the prototype by the addition of front and rear subframes to the unibody to take the suspension loads, and by turning the engine around with the carburettor at the back rather than at the front. This required an extra gear to be placed between engine and transmission to reverse the engine direction. Making this a reduction gear had the beneficial effect of reducing loads on the gearbox and preventing the rapid wear on the synchromesh which had been a problem on early prototypes. Having the caburettor at the rear helped to reduce carburettor icing, but did expose the distributor to water coming in through the grille. The engine size was reduced from 948 to 848 cc, which reduced the top speed from an unprecedented 90 mph (145 km/h) to a more manageable (for the time) 72 mph (116 km/h) — a decision that was reversed in 1967.

Despite its utilitarian origins, the classic Mini shape had become so iconic that by the 1990s Rover Group, the heirs to BMC, were able to register its design as a trade mark in its own right

1 comment:

Noticing rough idling, oil spills, or destitute fuel effectiveness? These are common Mini Cooper PCV valve symptoms. A flawed PCV valve can lead to increased engine pressure, execution issues, and indeed check engine lights. At Cerrones European, our talented professionals specialize in distinguishing and settling PCV valve issues in Smaller-than-expected Coopers, guaranteeing your engine runs easily and effectively. Believe us for accurate diagnostics and expert service.

Post a Comment